Production Systems Engineering (PSE) is an emerging area of Engineering intended to provide quantitative analytical methods for analysis, continuous improvement, and design of production systems. Every problem has its origin on the factory floor. Every solution obtained in PSE has been applied on the factory floor. PSE uses traditional terms, such as bottleneck, leanness, continuous improvement, etc., but infuses them with precise engineering knowledge and, thereby, offers a possibility of designing and managing production systems with the highest efficiency and guaranteed performance.

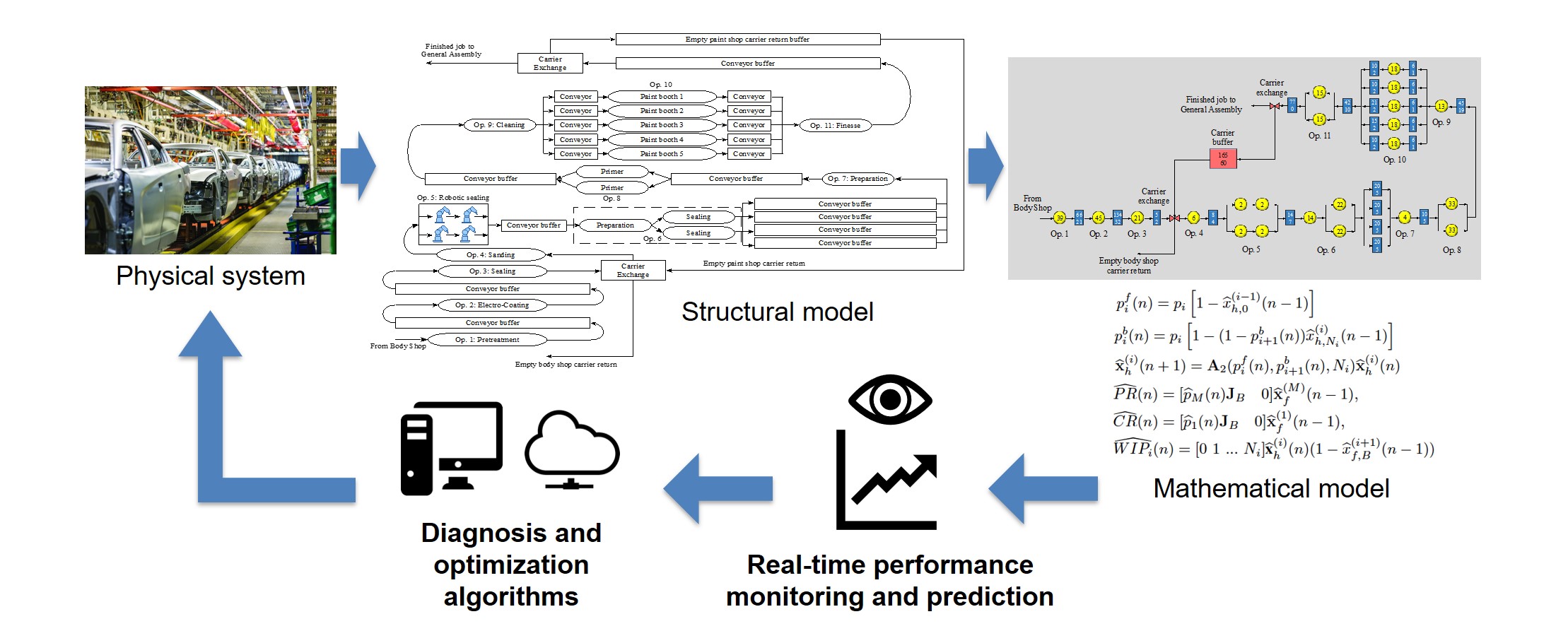

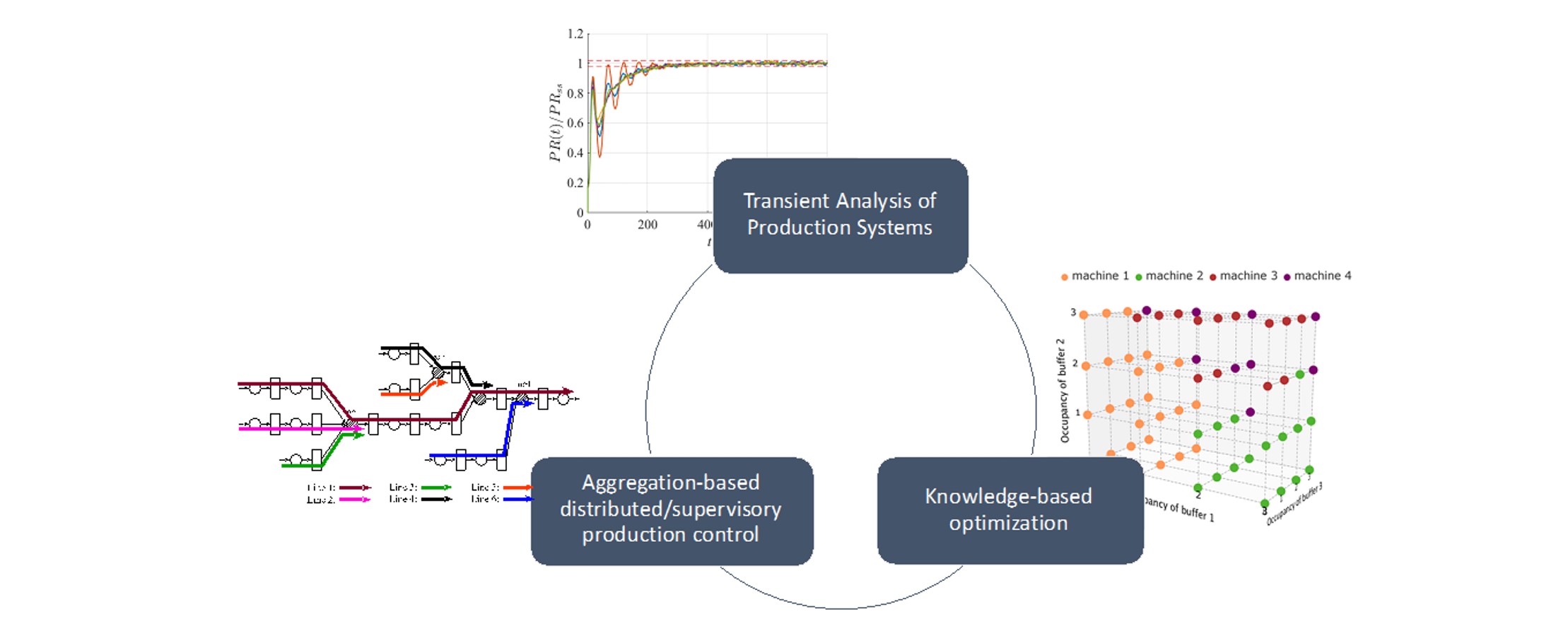

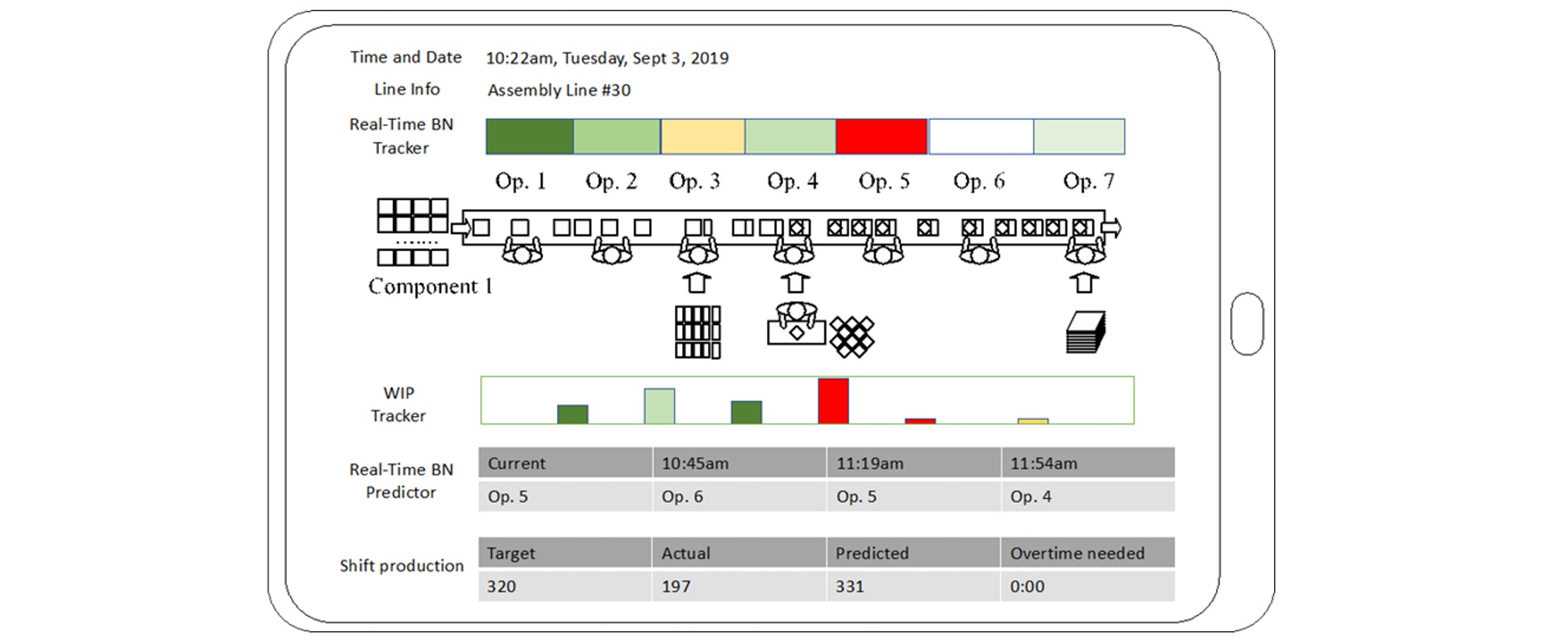

The approach of PSE is based on mathematical modeling of serial lines and assembly systems, with subsequent analyses based on recursive aggregation procedures. As a result, methods for solving the following problems are derived: Performance analysis; Bottleneck identification; Continuous improvement; Lean buffering design; Product quality; Raw material release control to ensure desired lead time. To enable applications, the PSE Toolbox, which implements the algorithms obtained in PSE, has been developed.

PSE has been applied to dozens of production systems in large, medium, and small manufacturing organizations. These include GM, Ford, Chrysler, Toyota, MillerCoors, Kraft Foods, Kroger, Lexmark, Subzero, Cree Lighting, HellermannTyton, etc. Consistently, significant improvements in productivity, quality, and customer demand satisfaction have been obtained.

News

- Our team took part in 9th SOE & SAGE Poster CompetitionOur team took part in 9th annual SOE & SAGE Poster Competition and made presentations on topics of data analytics for automated feature extraction and anomaly detection in industrial manufacturing process and an integrated dynamic control framework in smart manufacturing systems.Posted on June 2, 2023

- New paper accepted for publication in International Journal of Production ResearchNew paper titled “Recursive decomposition/aggregation algorithms for performance metrics calculation in multi-level assembly/disassembly production systems with exponential reliability machines” is accepted for publication in International Journal of Production Research. Congratulations!Posted on June 2, 2023

- New paper accepted for publication in Journal of Advanced Manufacturing and ProcessingNew paper titled “A simulation‐based integrated virtual testbed for dynamic optimization in smart manufacturing systems” is accepted for publication in Journal of Advanced Manufacturing and Processing. Congratulations!Posted on June 2, 2023

- Two papers accepted for presentation at CASE 2022Two papers titled “Detection and Correction of Buffer Occupancy Data Error in Two-Machine Bernoulli Serial Lines” and “A Novel Approach to Modeling of Production System: A Case Study at a Small/medium-sized Manufacturer” are accepted by the 18th IEEE Conference on Automation Science and Engineering.Posted on June 2, 2023

- The senior design guided by Professor Zhang was featured in local newsA team of ECE students worked under the direction of Professor Zhang to complete the senior design project, which was featured in the local news.Posted on June 27, 2022

Contact Us

| Phone: | 860-486-4462 |

|---|---|

| E-mail: | liang.zhang@uconn.edu |

| Address: | 371 Fairfield Way UNIT 4157 Storrs, CT 06029 |