New paper titled “Parameter Identification for Bernoulli Serial Production Line Model” is accepted for publication in IEEE Transactions on Automation Science and Engineering. Congratulations!

New paper titled “Parameter Identification for Bernoulli Serial Production Line Model” is accepted for publication in IEEE Transactions on Automation Science and Engineering. Congratulations!

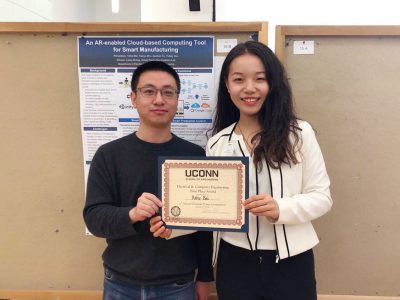

Our research on AR application of the manufacturing won the first place award in 6th annual graduate poster competition with Electrical & Computer Engineering department.

Professor Zhang’s paper on Smart Production Systems was awarded the Commended Paper Award of the 9th IFAC/IFIP/IFORS/IISE/INFORMS Conference on Manufacturing Modelling, Management and Control (MIM 2019), Berlin Germany.

Welcome two new Phd students: Tianyu Zhu and Yuting Sun join SPS Lab.

Professor Zhang and Yishu Bai attended 15th IEEE Conference on Automation Science and Engineering held at University of British Columbia, Vancouver, BC, Canada from August 22th to 26th. They both made presentations for papers on the conference. What’s more, Yishu gave a presentation in competition for the Best Student Paper Award.

Mengzhuo yang defended her master thesis successfully today. Congratulations!

Wish Mengzhuo all the best in the future.

Production Systems Engineering (PSE) is an emerging area of Engineering intended to provide quantitative analytical methods for analysis, continuous improvement, and design of production systems. Every problem has its origin on the factory floor. Every solution obtained in PSE has been applied on the factory floor. PSE uses traditional terms, such as bottleneck, leanness, continuous improvement, etc., but infuses them with precise engineering knowledge and, thereby, offers a possibility of designing and managing production systems with the highest efficiency and guaranteed performance.

The approach of PSE is based on mathematical modeling of serial lines and assembly systems, with subsequent analyses based on recursive aggregation procedures. As a result, methods for solving the following problems are derived: Performance analysis; Bottleneck identification; Continuous improvement; Lean buffering design; Product quality; Raw material release control to ensure desired lead time. To enable applications, the PSE Toolbox, which implements the algorithms obtained in PSE, has been developed.

PSE has been applied to dozens of production systems in large, medium, and small manufacturing organizations. These include GM, Ford, Chrysler, Toyota, MillerCoors, Kraft Foods, Kroger, Lexmark, Subzero, Ruud Lighting, HellermannTyton, etc. Consistently, significant improvements in productivity, quality, and customer demand satisfaction have been obtained.